I. Introduction

Uses: widely used in integrated circuit technology, fluorescent display, precision filter, micro-electrodes and so on.

II. Etching mesh technology advantage

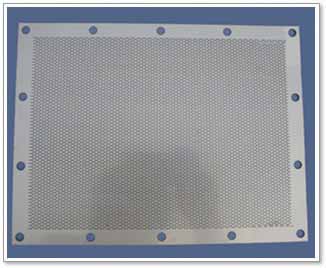

1, the mechanical production of the smallest wire diameter is 0.02mm

2, the largest production area is 500mm * 600mm

3, the material thickness is 0.02mm - 0.5mm

III. Etching mesh technology standard,

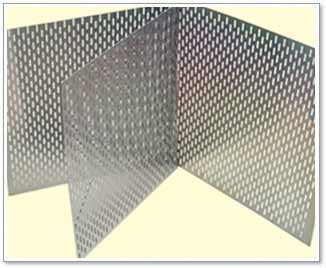

1, this technology improves traditional metal processing way.

2, this technique can use data, charts, columnar design and other complex concave to process convex metal products.

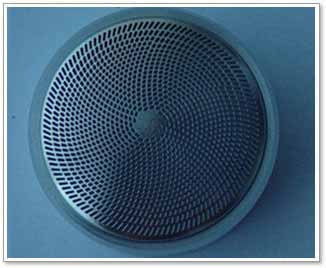

3, the etching can be used to make holes and other forms.

Fourth, the scope of application of chemical etching:

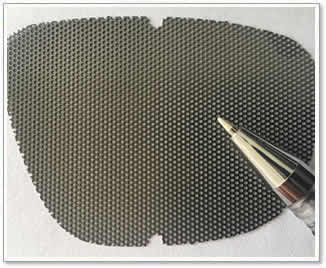

1, Machinable metal types: metal, alloy and stainless steel sheet, strip steel;

2, plate thickness range: 2mm and the following sheet, especially for the under 0.5mm sheet;

3, the industry uses:

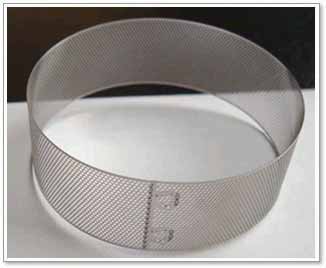

(1) petroleum, chemical, food, pharmaceutical precision filters, filter plates, filter cartridges, filters;

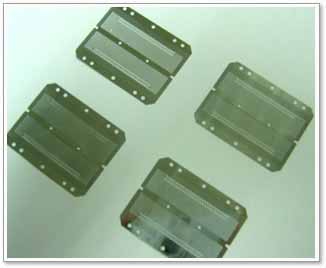

(2) the electronics industry metal drain plate, cover, flat pin, lead frame,metal substrate;

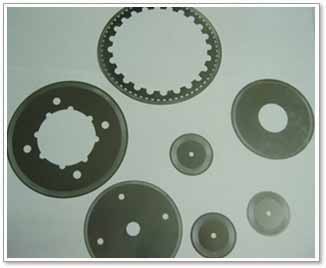

(3) precision optical and mechanical plane parts, springs parts;

(4) bump-type friction plate and other flat parts;

(5) metal plate and complex metal decorative panels and fine crafts.

|

|

|

|

|

|

|

|

|

|